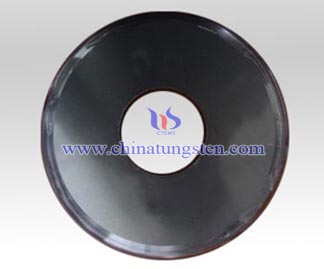

Tungsten Carbide Cutting Machine Blades

Tungsten carbide cutting machine blades,using solid carbide matrix, through multi-channel production process from finishing, sharp knife, cut iron drunk. Mainly used for electronic circuit boards face cutting jobs lead foot, component foot or feet and other plug-in LED lights on cutting machine, is commonly used in electronic hardware cutting tool products.

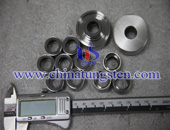

Production process:

Ingredients (according to the applicable requirements of selection of tungsten carbide powder and cobalt powder) → Mix → Smash → Drying → After sifting joined forming agent → Then drying → Sifting prepared mixes → Mixing granulation, pressing → Forming → Sintering → After firing blanks → Inspection → Ground plane → The grinding round and sink units → Cylindrical and coarse grinding the blade → Fine the blade → Appearance and dimensional accuracy test → blades test machine → Marking → 100% microscopic examination edge → Qualified product packaging.

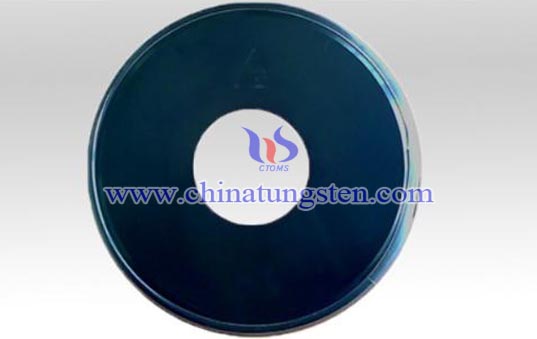

Tungsten carbide cutting machine blades, while having sharp edge, high hardness, high wear-resistant properties, but it has been in a state of high speed cutting during cutting work; well known that all things which the higher speed of operation heat generated by the higher wear faster but also produces metal thermal fatigue resistance lead to lower its hardness, wear resistance and hardness to reduce its sharpness will naturally decreases, and thus directly affect their cutting performance, coupled with PCB terminal material being cut (steel, stainless steel, copper, zinc, tin, iron, etc.) vary, soft, hard, thick, thin Jie, which will lead to cutting machine blades in the cutting edge for some time passivation is not a naturally sharp.

So, tungsten carbide cutting machine blades in use for some time is necessary for grinding the edge, according to our experience ten years cutting machine blade, cutting machine blades edge best choice when grinding mill way , because the cooling water mill water plays the role of tungsten steel can reduce or eliminate cutting machine blade grinding thermal fatigue resistance to a certain extent, thus maintaining its original characteristics.