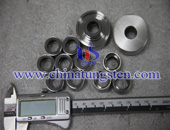

Tungsten Carbide Machine Clip Blades

Tungsten carbide machine clip blades is to avoid welding turning tungsten carbide blades for welding cracks so, reduce tool life, desoldering and Arbor used only once when using other shortcomings, the use of the blade with mechanical clamping method fixed on the shank, blunt blades can be replaced with a new blades sharpening a good turning.

Tungsten carbide machine clip blades without welding temperature, the hardness of blades can be avoided due to high temperature caused by the welding drop and generation of cracks and other defects. Therefore, to improve tool life and tool holders can be used repeatedly. Commonly used machine turning organic clip clip-turning inserts, milling machine clip blade, clamp screw blade, clamp off the blade.

Tungsten carbide machine clip blades structure form

1. The pressure

And a pressing plate with screw blades from above, by adjusting the position of the screw to adjust the blades.

Features: simple structure, reliable clamping paperback, easy to use, blades, with a blunt behind after regrinding. Is the largest on-pressure processing an application.

2. Weldon

This form is generally more use of the blade itself slope, by the side of the wedge and screw to clamp the blade from the blade.

Features: Blade vertical loading of sipes manufacturing precision requirements may be appropriate to reduce the blade with a blunt front after regrinding.

3. Cutting force clip

This form usually refers to the self-locking lathe cutting force, it is the use of the Turning the process of cutting force, blade clamping 1:30 chute.

Features: simple structure, easy to use, but requires close coordination with the blade knife slot, shock and vibration-free cutting.