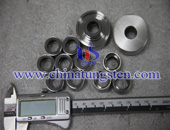

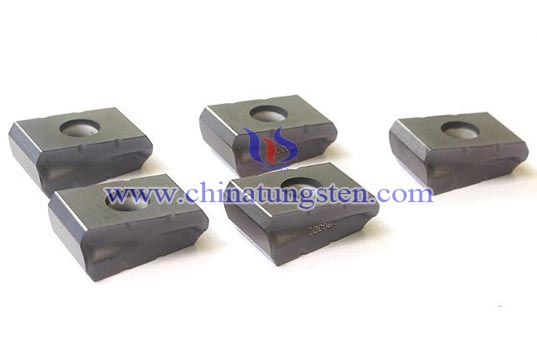

Tungsten Carbide Indexable Blades

Tungsten carbide indexable blades are tool that will be able to use the polygon indexable blades mechanically clamped on the arbor or cutter body. In the cutting process, when a blunt blade tip, will use the additional indexing blades after blade tip, the blades with a blunt no regrinding. Most of indexable cutting tools with carbide blades, there is also a ceramic polycrystalline cubic boron nitride or polycrystalline diamond. From 1949 to 1950, the United States developed the first mechanical clamping into indexable turning tools, and in 1954 began selling called disposable (throw-away) indexable inserts and turning merchandise. China has called this tool as "throwaway knives."

Indexable blades compared with the welding tools has the following advantages:

1) blades become independent functional element has been expanded and enhanced cutting;

2) mechanical clip-welding process to avoid the impact and limitations, more conducive to select the blades according to the processing of various materials objects and give full play to its cutting, resulting in improved cutting efficiency;

|

3) cutting edge space fixed position relative to the cutter body, saving tool change, the time required to assist knives, improve the utilization of the machine; 4) Due to the high efficiency of indexable cutting tool, less auxiliary time, it improves the working efficiency and indexable cutter blade can be reused, saving the steel and manufacturing costs, so its economy is good. Development of indexable cutting tools greatly contributed to the progress of tool technology, and can turn professional position the cutter body, but also promoted the development of standardized production blade manufacturing process. |

|

Tungsten carbide indexable blades selected models divided into four steps:

1.Select the blades clamping system

According to choose the right cutting blades clamping manner, the blade clamping system performance into 1-5, where 5 is the best choice.

2.Select indexable blades type

To consider when selecting indexable blades model various factors, select blades shape code based on the shape of machined parts; select the main cutting edge angle code based on material machining; select blades size tolerance code based machining accuracy; according to the processing asked to select pieces of debris and knife clamped in the form of code; select blades cutting edge length code based on the choice of cutting parameters; Moreover, you should choose a knife fragment crumbs Groove; compute blade cutting edge length by the theoretical formula.

3.Select the blades tip arc

When you press roughing tool nose radius largest selection of cut away, or take the knife knives amount calculated by the empirical formula; press finishing surface roughness when calculating the amount of finishing pass.

4.Select the blades material grades

International ISO standard Tungsten carbide blades material put into P, K, M three categories, namely the processing of steel, cast iron, steel and processed material is not easy. According to the hardness of the material and its turning of the workpiece, the choice of cutting parameters to select the indexable blades material grades.